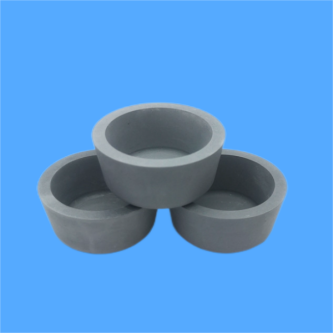

High Voltage Ceramic Connectors

Innovacera’s High Voltage Ceramic Connectors deliver exceptional electrical insulation and thermal stability for demanding applications. Engineered with precision, our ceramic connectors ensure reliable performance under extreme voltages, harsh environments, and high-pressure conditions. Our robust portfolio including pressure-bearing petroleum connectors, compact micro-rectangular and micro-D series, and versatile multi-pin solutions—all leveraging advanced ceramic materials for superior safety and durability in critical industrial, aerospace, and energy sectors.

Enquiry

Enquiry