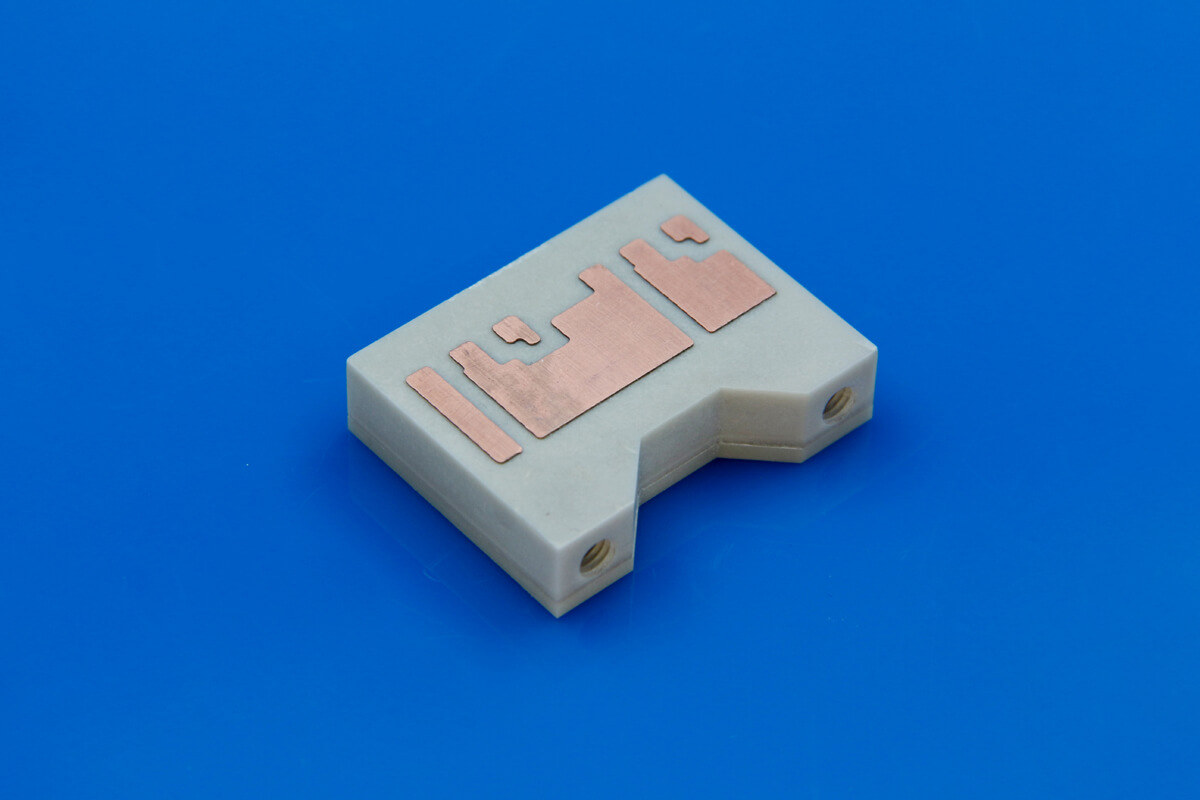

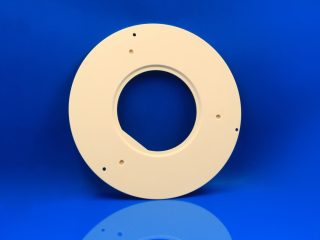

When perform brazing (for example, Ag) in the H2 environment and it requires extreme heat and energy cycle resistance, with unique high and low temperature impact resistance, AMB substrates become an ideal packaging material for new generation semiconductor (SIC) and new high power electronic devices, it retains good thermal stability even beyond 1000 cycles.

The copper thickness is 0.1-0.5mm, provides very high ampacity and very good heat spreading. This makes it a preferred material for the applications:

-IGBT

-Power Modules

-Automotive Power Electronics

-Renewable Energy

-Space and Industrial

-Others

Enquiry

Enquiry