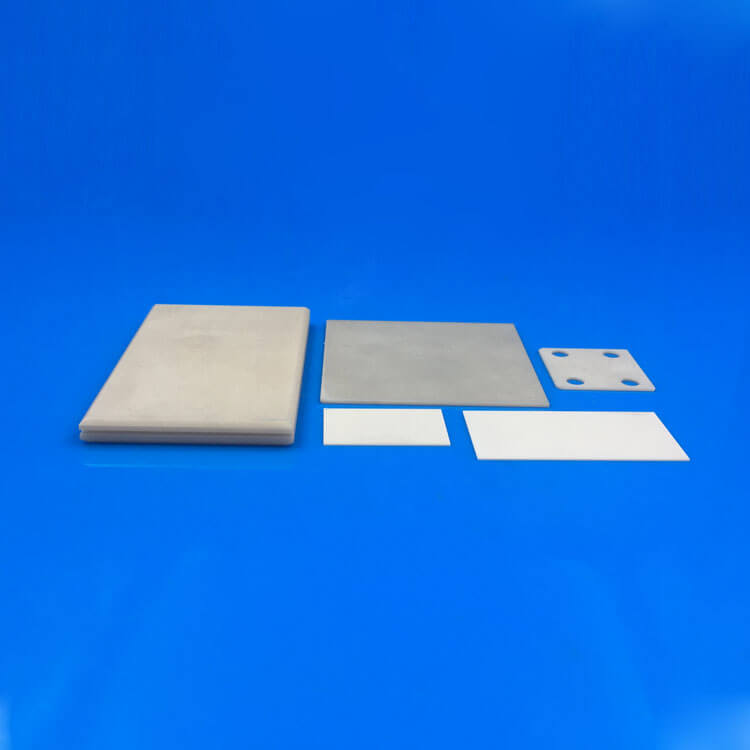

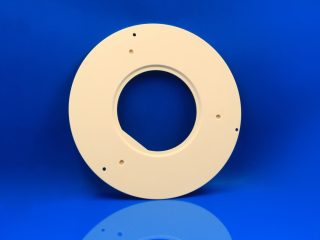

Ceramic substrate refers to copper foil directly bonded to alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate surface (single or double sided) at high temperature on a special process plate. The ultrathin composite substrate has excellent electrical insulation performance, high thermal conductivity, excellent soft brazing and high adhesion strength, and can be etched into a variety of graphics like PCB board, with great current-carrying capacity. Therefore, ceramic substrate has become the basic material of high power electronic circuit structure technology and interconnection technology.

Purpose:

High-power semiconductor module; Semiconductor cooler, electronic heater; Power control circuit, power mixing circuit.

Intelligent power module; High frequency switching power supply, solid state relay.

Automotive electronics, aerospace and military electronics components.

Solar panel module; Telecommunications private exchange, receiving system; Laser and other industrial electronics.

Features:

Strong mechanical stress, stable shape; High strength, high thermal conductivity, high insulation; Strong binding force, anti-corrosion.

Excellent thermal cycle performance, cycle times up to 50,000, high reliability.

And PCB board (or IMS substrate) can be etched out of a variety of graphic structure; No pollution, no pollution.

Ceramic Substrate Use temperature range -55℃ ~ 850℃; Thermal expansion coefficient is close to silicon, simplifying the production process of power module.

Aluminum Nitride Ceramic Substrate

Enquiry

Enquiry