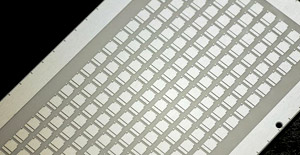

DPC (Direct Plated Copper) Metallized Ceramic Substrate

Smaller, Thinner Thin Film, Thick Film Design.

Better Heat Dissipation; Longer Lifetime DPC Substrate

Why DPC Metallized Substrate?

DPC is created for better electrical performance and flexibility because of fine line capability and solid copper via fill. DPC is also a cost-effective alternative for the reasons of more flexible manufacturing capability, especially for thinner metallization.

Comparison Of DPC To Other Technologies

|

Key Attributes |

DPC |

Thin Film |

Thick Film |

|

Conductor Electrical Conductivity |

Very good. Thick copper conductor. |

Poor conductivity due to very thin film thickness. |

Good conductivity. Lowered by the presence of the glass phase. |

|

Via Electrical Conductivity |

Very good. Vias filled with pure copper. |

Very good. Vias filled with pure copper. |

Poor. Vias filled with 50% metal and 50% glass or pores. |

|

Feature Resolution |

Goood. Depends on Cu thickness. |

Very good. |

Goood. Determined by screen print capability. |

|

Cost |

Low to moderate. Vias and metal deposited in the same process. |

High cost. Expensive substrate. Lapp and polish required after via deposition. |

Low to moderate. Expensive metal pastes. Low cost substrate and low cost deposition technology. |

|

Thermal Performance |

Very good. AIN or alumina substrate and high thermal conductivity metal. |

Good. AIN or alumina substrate. Metal layer too thin for heat spreading. |

Moderate. Alumina substrate. Conductivity through the metal is poor due to the glass phase. |

|

Suitability for Power Applications |

Very suitable. Copper conductors carry high currents. |

Not suitable. Thin film layers can not carry high currents. |

Suitable. Conductors with a glass phase have moderate conductivity. |

|

Suitability for High Frequency Applications |

Suitable. Good conductivity and line resolution |

Very suitable. Excellent line resolution. |

Not suitable. |

|

Green |

Yes |

Yes |

No. Often contain Pb additives. |

Summary

Overall, copper plating performs superior compared to other technologies in terms of its features and applications.

DPC Substrate Features:

Higher circuit density

Outstanding high-frequency characteristics

Excellent thermal management and heat-transfer performance

Outstanding solderability and wire-bonding assembly characteristics

Low tooling costs and quick turnaround of prototypes

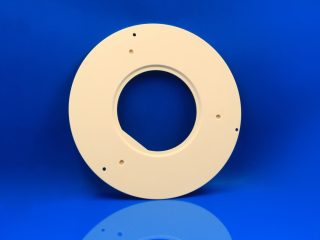

Applications of DPC:

HBLED

Substrates for solar concentrator cells

Power semiconductor packaging including automotive motor control

Hybrid and electric automobile power management electronics

Packages for RF

Microwave devices

Enquiry

Enquiry